These days, everyone is talking about sustainability. From governments to consumers, there’s growing pressure on manufacturers to reduce waste and find smarter ways to use resources. One of the biggest challenges? Plastic. It’s everywhere in our daily lives, but too much of it ends up in landfills or oceans.

That’s where plastic recycling and injection molding machines come together as a powerful solution.

Why Recycling Plastic Matters

Plastic waste isn’t just an environmental issue—it’s also a missed opportunity. Every ton of plastic that gets recycled is material that doesn’t need to be made from scratch. That means fewer carbon emissions, less oil consumption, and less trash piling up in the wrong places.

Where Injection Molding Fits In

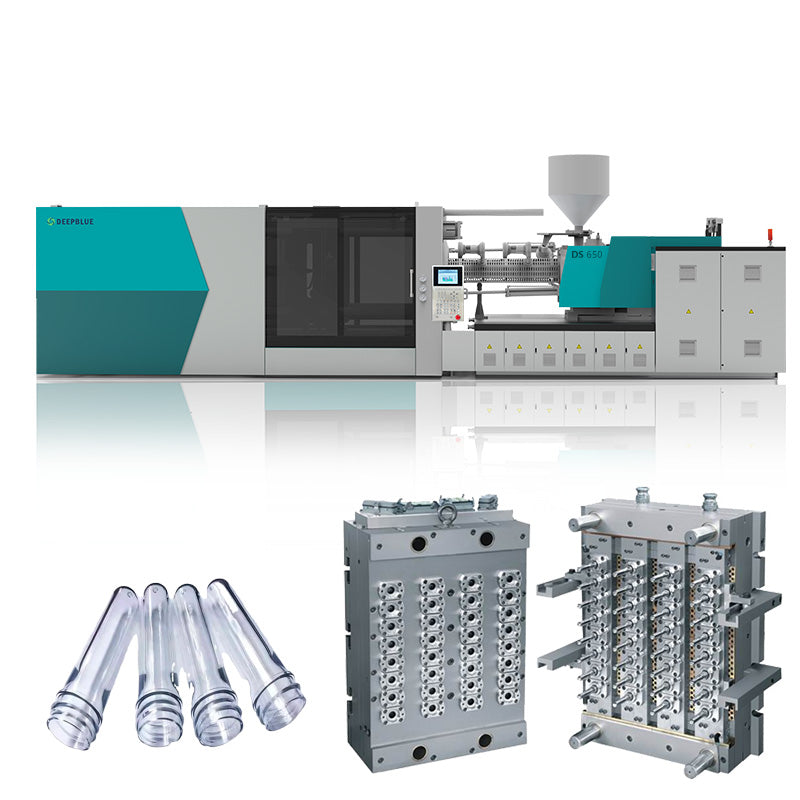

Injection molding machines aren’t just for making new plastic parts—they’re also perfect for giving recycled plastics a second life. Instead of relying only on virgin resin, manufacturers can now feed recycled pellets (like rPET, rPP, or rPE) into the machine and produce high-quality products that look and perform just like those made from new materials.

Some of the benefits are pretty clear:

-

Less virgin plastic needed → lower cost and less strain on the planet.

-

Energy savings → modern machines are designed to run more efficiently.

-

Versatility → recycled plastics can be turned into crates, furniture, packaging, and even industrial parts.

-

More competitive pricing → saving on raw materials often means better market positioning.

How This Supports ESG Goals

If your company is serious about ESG (Environmental, Social, and Governance), injection molding with recycled plastics is a practical step forward:

-

Environmental: fewer emissions, less waste, and smarter use of resources.

-

Social: meeting customer demand for eco-friendly products and supporting the recycling industry.

-

Governance: staying compliant with sustainability regulations and showing real commitment—not just greenwashing.

Looking Ahead

The future of manufacturing is moving toward closed-loop systems where every piece of scrap, every defective part, and even used products are collected, recycled, and molded back into new items. That’s how industries can truly shift from “use and throw” to “use and reuse.”

Final Thoughts

Recycling plastic through injection molding isn’t just about cutting costs—it’s about taking responsibility and building a stronger, greener brand. Companies that adopt this approach don’t just keep up with ESG requirements—they stand out as leaders in sustainable manufacturing.

At DeepBlue Smart Equipment, we’re helping manufacturers worldwide run more efficiently with machines designed to handle recycled materials. It’s good for business, and it’s good for the planet.